Automatic fan control. We control the cooler (thermal control of fans in practice) Temperature regulator for a 12V fan

Thermostats are widely used in modern appliances, automobiles, heating and air conditioning systems, manufacturing, refrigeration and furnace applications. The operating principle of any thermostat is based on turning on or off various devices after reaching certain temperature values.

Modern digital thermostats are controlled using buttons: touch or regular. Many models also come with a digital panel that displays the set temperature. The group of programmable thermostats is the most expensive. Using the device, you can provide for temperature changes hourly or set the required mode for a week in advance. The device can be controlled remotely: via a smartphone or computer.

For a complex technological process, for example, a steel-smelting furnace, making a thermostat with your own hands is a rather difficult task that requires serious knowledge. But any home craftsman can assemble a small device for a cooler or incubator.

In order to understand how a temperature controller works, consider a simple device that is used to open and close the damper of a mine boiler and is activated when the air is heated.

To operate the device, 2 aluminum pipes, 2 levers, a return spring, a chain that goes to the boiler, and an adjustment unit in the form of a faucet axle box were used. All components were installed on the boiler.

As is known, the coefficient of linear thermal expansion of aluminum is 22x10-6 0C. When an aluminum pipe with a length of one and a half meters, a width of 0.02 m and a thickness of 0.01 m is heated to 130 degrees Celsius, an elongation of 4.29 mm occurs. When heated, the pipes expand, causing the levers to shift and the damper to close. When cooling, the pipes decrease in length, and the levers open the damper. The main problem when using this scheme is that it is very difficult to accurately determine the response threshold of the thermostat. Today, preference is given to devices based on electronic elements.

Scheme of operation of a simple thermostat

Typically, relay-based circuits are used to maintain a set temperature. The main elements included in this equipment are:

- temperature sensor;

- threshold circuit;

- actuator or indicator device.

Semiconductor elements, thermistors, resistance thermometers, thermocouples and bimetallic thermal relays can be used as sensors.

The thermostat circuit reacts when the parameter exceeds a given level and turns on the actuator. The simplest version of such a device is an element based on bipolar transistors. The thermal relay is based on a Schmidt trigger. A thermistor acts as a temperature sensor - an element whose resistance changes depending on the increase or decrease in degrees.

R1 is a potentiometer that sets the initial offset on thermistor R2 and potentiometer R3. Due to the adjustment, the actuator is activated and relay K1 is switched when the resistance of the thermistor changes. In this case, the operating voltage of the relay must correspond to the operating power supply of the equipment. To protect the output transistor from voltage surges, a semiconductor diode is connected in parallel. The load value of the connected element depends on the maximum current of the electromagnetic relay.

Attention! On the Internet you can see pictures with thermostat drawings for various equipment. But quite often the image and description do not correspond to each other. Sometimes the pictures may simply show other devices. Therefore, production can begin only after carefully studying all the information.

Before starting work, you should decide on the power of the future thermostat and the temperature range in which it will operate. The refrigerator will require some elements, and the heating will require others.

Three element thermostat

One of the elementary devices, using an example of which you can assemble and understand the principle of operation, is a simple do-it-yourself thermostat designed for a fan in a PC. All work is done on a breadboard. If there are problems with the pin, then you can use a solderless board.

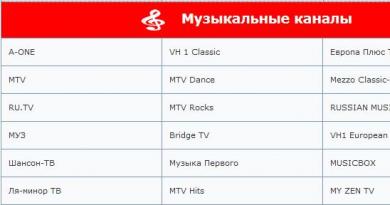

The thermostat circuit in this case consists of only three elements:

- power MOSFET transistor (N channel), you can use IRFZ24N MOSFET 12 V and 10 A or IFR510 Power MOSFET;

- potentiometer 10 kOhm;

- NTC thermistor 10 kOhm, which will act as a temperature sensor.

The temperature sensor reacts to an increase in degrees, due to which the entire circuit is activated and the fan turns on.

Now let's move on to the setup. To do this, turn on the computer and adjust the potentiometer, setting the value for the fan turned off. At the moment when the temperature approaches critical, we reduce the resistance as much as possible before the blades rotate very slowly. It is better to do the setup several times to make sure the equipment is working effectively.

The modern electronics industry offers elements and microcircuits that differ significantly in appearance and technical characteristics. Each resistance or relay has several analogues. It is not necessary to use only those elements that are indicated in the diagram; you can take others that match the parameters of the samples.

Thermostats for heating boilers

When adjusting heating systems, it is important to accurately calibrate the device. To do this you will need a voltage and current meter. To create a working system, you can use the following diagram.

Using this scheme, you can create external equipment for monitoring a solid fuel boiler. The role of the zener diode here is performed by the K561LA7 microcircuit. The operation of the device is based on the ability of a thermistor to reduce resistance when heated. The resistor is connected to the electricity voltage divider network. The required temperature can be set using variable resistor R2. The voltage is supplied to the 2I-NOT inverter. The resulting current is supplied to capacitor C1. A capacitor is connected to 2I-NOT, which controls the operation of one trigger. The latter is connected to the second trigger.

Temperature control proceeds according to the following scheme:

- as the degrees drop, the voltage in the relay increases;

- when a certain value is reached, the fan that is connected to the relay turns off.

It is better to solder on a mole rat. As a battery, you can take any device operating within 3-15 V.

Carefully! Installing homemade devices for any purpose on heating systems can lead to equipment failure. Moreover, the use of such devices may be prohibited at the level of services providing communications in your home.

Digital thermostat

In order to create a fully functioning thermostat with accurate calibration, you cannot do without digital elements. Consider a device for monitoring temperatures in a small storage area for vegetables.

The main element here is the PIC16F628A microcontroller. This chip provides control of various electronic devices. The PIC16F628A microcontroller contains 2 analog comparators, an internal oscillator, 3 timers, CCP comparison modules and USART data transfer exchange modules.

When the thermostat is operating, the value of the existing and set temperature is supplied to MT30361 - a three-digit indicator with a common cathode. In order to set the required temperature, use the following buttons: SB1 – to decrease and SB2 – to increase. If you carry out the adjustment while simultaneously pressing the SB3 button, you can set the hysteresis values. The minimum hysteresis value for this circuit is 1 degree. A detailed drawing can be seen on the plan.

When creating any of the devices, it is important not only to correctly solder the circuit itself, but also to think about how best to place the equipment. It is necessary that the board itself is protected from moisture and dust, otherwise short circuits and failure of individual elements cannot be avoided. You should also take care to insulate all contacts.

Video

Today we will look at the principle of operation of the radiator cooling system, or more precisely the fan control system. A fan in a car serves to cool the engine when it heats up, but constant operation of the fan is not required at all, firstly, it is pointless when the radiator does not require additional cooling, and secondly, constant operation of the fan greatly loads the on-board network, which is also not good.

Therefore, we need to ensure that the fan turns on when the radiator (or the liquid in it) gets hot enough. The circuit itself is shown in the drawing below; in addition to turning on at a certain temperature, the circuit ensures smooth activation of the fan and reduces sound noise, which will have a good effect on the service life of the fan.

The main element in the circuit is a thermistor with a negative temperature dependence coefficient. The operating resistance is 5-50 kOhm, it all depends on the brand of thermistor. The thermistor is welded directly to the radiator. The operation is very important, the thermistor must touch the radiator; if the welding is bad, then everything will have to be redone, so we pay special attention to this point.

All values or their definition are described in the diagram; to select R1, we measure the resistance value of the thermistor with a multimeter and divide it by 5. The result will give you an idea of the approximate range of the value of the variable resistor. We set the required resistor values, solder the circuit and begin debugging the operation of the device.

The RC circuit shown in the diagram is indicated by a dashed line because it is not always required. If during debugging the circuit becomes “chondrous”, it will need to be added. By rotating the variable resistor and measuring the temperature of the radiator with a third-party device, we set the temperature we need to turn on the fan.

The fan is a fairly powerful device, so we must install the transistor that switches the current through it on a heat sink or on the car body, but in this case it is necessary to ensure the insulation of the transistor body from the body, this is usually done using a mica gasket. As a replacement for KT815, you can take KT819 or a foreign analogue.

Share to:Not long ago I came across an enhance p520n power supply from a home computer. In addition to the main board of the power supply, another small device was found in it. It was a fan speed thermostat. The circuit is simple, containing only two transistors, four resistors, a diode and a capacitor. The device diagram is shown in Figure 1.

This regulator can be used not only for power supplies, but also in low-frequency power amplifiers, welding machines, powerful converters, power regulators, etc. Why buzz in vain if all SCPs (semiconductor devices) are cold. The vd1 diode located on the board and in the indicated circuit is most likely needed only in a specific SMPS, so it can be removed. There is a 1n4002 diode on the board. The first transistor can be replaced with a domestic one - KT3102. According to the documentation, the imported transistor c1384 is designed for a collector current of 1A, a collector-emitter voltage of 60V, and a constant collector power dissipation of 1 watt. You can try replacing it with our KT814 with any letter or with KT972. The electrolytic capacitor must be rated at 16 volts.

The initial fan rotation speed is selected by changing the resistance value of resistor r1. The scheme works as follows. When the temperature inside the controlled volume or directly at the heat sink of the PP is low, the transistor vt2 is closed and the fan has a low rotation speed. As the temperature increases, the resistance of the thermistor rt begins to decrease, which in turn will lead to a decrease in the voltage at the base vt1, and the collector current of this transistor will also begin to decrease. A decrease in the current through the first transistor will lead to an increase in the base-emitter current of the second transistor vt2 (the shunting effect of transistor vt1 on the base-emitter junction vt2 will decrease). Transistor vt2 will begin to open, the voltage on the fan will begin to increase, and its rotation speed will increase.

For greater versatility, you can introduce a voltage stabilizer into the circuit, for example, KR142EN8B. This microcircuit has a maximum input voltage over the entire temperature range of 35 volts.

The board view is shown in Photo 1, and the printed circuit board drawing is shown in Figure 2.

If surface mounting is used, the board can be mounted directly on the controlled heat sink for the PCB by making a corresponding hole in it for the fastening screw. Chapter:

If surface mounting is used, the board can be mounted directly on the controlled heat sink for the PCB by making a corresponding hole in it for the fastening screw. Chapter: Tillmann Steinbrecher

The main problem with air-cooled PCs is noise. As the fan speed increases, the noise also increases. Noise is annoying and negatively affects our health and productivity.

So why not start fighting it? The solution is a thermostat. In most PCs, fans spin at maximum speed, regardless of processor load and external temperature. Modern PC fans have built-in thermostats, as do some motherboards.

The idea of using a thermostat in itself is not new; now fans with a thermoregulation function are quite common. Unfortunately, most of them have their drawbacks:

- The processor temperature is set automatically. The disadvantage of this approach is the inability to adjust the fan to a specific processor model (the operating temperatures of different processors differ). Obviously, such fans are completely unsuitable for overclocking.

- Most fans regulate the speed of the blades, but cannot turn off completely. This is especially true for fans used in PC cases. In addition, there are processors that, if there is no load, do not require cooling at all.

- Each fan requires a separate sensor. Therefore, the best solution would be to create a thermostat for the fan yourself.

For the ridiculous price of $4, the thermostat will have the following features:

- The ability to adjust the temperature by the user. The temperature can be adjusted over a wide range, so the thermostat can be used both for fans used in the PC case and for fans used with the processor.

- The fan turns off if the temperature reaches a certain minimum.

- Possibility of simultaneous use of one sensor with several fans. So, now, having finished with the theory, you can proceed directly to assembling the device.

We only need three (!) elements:

- Power MOSFET transistor (N channel)

- Potentiometer 10 kOhm

- NTC temperature sensor with 10 kOhm resistance (thermistor)

Getting any element will not be difficult. There are no special requirements for MOSFET - voltage more than 12 V. When assembling the device, IRFZ24N MOSFET 12 V and 10 A was used. For US residents - IFR510 Power MOSFET.

Potentiometer - any. And finally, the NTC thermistor. You can use any thermistor, the only parameters are resistance (10 kOhm) and price (minimum).

You may need:

- Bread board. Optional, but still worth using for convenience.

- Radiator for transistor. Under normal conditions this is not necessary, but if more than three fans are used, it will still have to be installed.

Warnings!!!

Make sure you insulate the device well. Do not allow the device to come into contact with the case or other elements of the PC. Fan speed measurement will not work. Do not try to connect the signal wire to the motherboard - this may damage it. Now you need to set up the thermostat. To do this, turn on the “cold” computer.

We adjust the resistance of the potentiometer and set it to a value at which the fan blades do not rotate. When the temperature begins to approach the maximum, reduce the resistance until the fan begins to rotate weakly. Take the time to adjust the required resistance, because... The efficiency of the entire device depends on this. If the settings are incorrect, the computer will overheat or the fans will run at maximum power all the time. If you have added an additional fan, you will need to adjust the thermostat again.

Attention!

You assemble this device at your own risk; the author does not bear any responsibility for the consequences of using this device.

First, the thermostat. When choosing a circuit, factors such as its simplicity, availability of elements (radio components) necessary for assembly, especially those used as temperature sensors, manufacturability of assembly and installation in the power supply housing were taken into account.

According to these criteria, in our opinion, V. Portunov’s scheme turned out to be the most successful. It allows you to reduce wear on the fan and reduce the noise level created by it. The diagram of this automatic fan speed controller is shown in Fig. 1. The temperature sensor is diodes VD1-VD4, connected in the opposite direction to the base circuit of the composite transistor VT1, VT2. The choice of diodes as a sensor determined the dependence of their reverse current on temperature, which is more pronounced than the similar dependence of the resistance of thermistors. In addition, the glass housing of these diodes allows you to do without any dielectric spacers when installing power supply transistors on the heat sink. The prevalence of diodes and their accessibility to radio amateurs played an important role.

Resistor R1 eliminates the possibility of failure of transistors VTI, VT2 in the event of thermal breakdown of the diodes (for example, when the fan motor is jammed). Its resistance is selected based on the maximum permissible value of the base current VT1. Resistor R2 determines the response threshold of the regulator.

Fig.1

It should be noted that the number of diodes of the temperature sensor depends on the static current transfer coefficient of the composite transistor VT1,VT2. If, with the resistance of resistor R2 indicated in the diagram, room temperature and the power on, the fan impeller is motionless, the number of diodes should be increased. It is necessary to ensure that after the supply voltage is applied, it confidently begins to rotate at a low frequency. Naturally, if the rotation speed is too high with four sensor diodes, the number of diodes should be reduced.

The device is mounted in the power supply housing. The terminals of the diodes VD1-VD4 of the same name are soldered together, placing their cases in the same plane close to each other. The resulting block is glued with BF-2 glue (or any other heat-resistant, for example, epoxy) to the heat sink of high-voltage transistors on the reverse side. Transistor VT2 with resistors R1, R2 and transistor VT1 soldered to its terminals (Fig. 2) is installed with the emitter output in the “+12 V fan” hole of the power supply board (previously the red wire from the fan was connected there). Setting up the device comes down to selecting resistor R2 2.. 3 minutes after turning on the PC and warming up the power supply transistors. Temporarily replacing R2 with a variable (100-150 kOhm), select such a resistance so that at rated load the heat sinks of the power supply transistors heat up no more than 40 ºС.

To avoid electric shock (heat sinks are under high voltage!), you can only “measure” the temperature by touch after turning off the computer.

A simple and reliable scheme was proposed by I. Lavrushov (UA6HJQ). The principle of its operation is the same as in the previous circuit, however, an NTC thermistor is used as a temperature sensor (the 10 kOhm rating is not critical). The transistor in the circuit is selected as KT503. As determined experimentally, its operation is more stable than other types of transistors. It is advisable to use a multi-turn trimmer, which will allow you to more accurately adjust the temperature threshold of the transistor and, accordingly, the fan speed. The thermistor is glued to the 12 V diode assembly. If it is missing, it can be replaced with two diodes. More powerful fans with a current consumption of more than 100 mA should be connected through a compound transistor circuit (the second KT815 transistor).

Fig.3

Diagrams of the other two, relatively simple and inexpensive PSU cooling fan speed controllers, are often provided on the Internet (CQHAM.ru). Their peculiarity is that the TL431 integral stabilizer is used as a threshold element. You can quite easily “get” this chip by disassembling old ATX PC power supplies.

The author of the first diagram (Fig. 4) is Ivan Shor (RA3WDK). Upon repetition, it became clear that it was advisable to use a multi-turn resistor of the same value as a tuning resistor R1. The thermistor is attached to the radiator of the cooled diode assembly (or to its body) using KPT-80 thermal paste.

Fig.4

A similar circuit, but on two KT503 connected in parallel (instead of one KT815), was used by Alexander (RX3DUR). With the component ratings indicated in the diagram (Fig. 5), 7V is supplied to the fan, increasing when the thermistor heats up. KT503 transistors can be replaced with imported 2SC945, all resistors with a power of 0.25 W.

A more complex cooling fan speed controller circuit is described in. It has been successfully used in other power supplies for a long time. Unlike the prototype, it uses “television” transistors. I will refer readers to the article on our website “Another universal power supply” and the archive, which presents a version of the printed circuit board (Fig. 5 in the archive) and a magazine source. The role of the radiator of the adjustable transistor T2 on it is performed by a free section of foil left on the front side of the board. This circuit allows, in addition to automatically increasing the fan speed when the radiator of the cooled power supply transistors or diode assembly heats up, to set the minimum threshold speed manually, up to the maximum.

Fig.6